Ancillary Equipment

Hestico remains at the forefront of the plastics and packaging industries, not only by providing essential equipment but also through our selection of Ancillary Equipment tailored for a variety of applications. Recognising the importance of advanced Ultrasonic Welding Machines and Ultrasonic Welding Generators, we ensure that our product range satisfies our clients’ welding and cutting requirements with precision and reliability.

Our portfolio is further enriched with sophisticated Injection Molding Equipment designed to optimise your production line. At Hestico, we understand that the right ancillary tools are as crucial as primary equipment in delivering a smooth, efficient, and productive manufacturing process.

As you delve into our range of blending and material handling systems, you will discover solutions specifically designed to streamline your processes. Efficient blending of materials is essential for consistent product quality, and our advanced blending systems ensure homogeneous mixing with precision control. Alongside these, our state-of-the-art drying systems address the unique challenges of moisture-sensitive materials, providing the optimal drying environment to preserve the integrity of your products.

Incorporating central feeding systems into your operation can significantly enhance productivity by automating the delivery of materials to the processing equipment. This not only reduces manual handling but also ensures a continuous, controlled flow of materials, which is crucial for maintaining production consistency and reducing waste.

Explore our complete selection of blending systems, drying solutions, and central feeding systems to discover how Hestico’s Ancillary Equipment can refine your operational processes and bolster product excellence.

Blending, drying and central feeding system

Ultrasonic welding

RINCO developing and manufacturing high-performance ultrasonic welding and cutting machines for 30 years. . RINCO ULTRASONICS AG is one of the leading producers of ultrasonic thermoplastic welding machines . The Rinco Product Range includes: Ultrasonic Welding Machines, Ultrasonic Welding Generators, Hand Welding Units, Cutting Units and Components.

Loaders, hot air dryers and mould temperature controllers

YANN BANG, is a specialist manufacturer of automatic auxiliary conveying and drying system for plastic and rubber industry in Taiwan and was founded in 1974. Continuous R&D over four decades, we were awarded several patents in Taiwan, Japan, USA, Germany, and China. With the honour of “Taiwan Symbol of Excellence Winner”, CE certification, ISO 9001, we supply the best quality and service to 80 countries, globally. Yann Bang has a complete products line and provide total solutions to your production facility such as drying system, dosing system, temperature heating & cooling system, conveying system, recycling system, and more.

Loaders, hot air dryers and mould temperature controllers

Anhui Kaifeng Plastic Machinery Co., Ltd. is a manufacturing enterprise in the field of plastic auxiliary equipment and industrial temperature control integrating manufacturing, sales, and service. Equipment includes conveying systems, temperature heating systems, cooling systems and much more. It relies on excellent manufacturing experience, implements the management mechanism of quality control and responsibility system, and strictly implements the ISO9001 international quality system certification standard. With advanced production technology, Kaifeng machinery has won the trust and support of most users. Its products are widely used in plastics, medicine, papermaking, food, chemical industry, metal electroplating, electronics, optics, DVD discs, textiles, spraying, magnesium alloy die casting, rubber, tires, extrusion Equipment for civil and other industries. The air-cooled chillers, water-cooled chillers and other products are exported to India, Malaysia, Vietnam, Singapore, Thailand and other countries, and OEM products are manufactured for peers at home and abroad.

Granulators and Shredders

TRIA is one of the most qualified producer of blades granulators, shredders, conveying and treatment system of plastics waste from plastic processing.

Injection moulding: Granulators up to 200 m/Tons, in line runners up to 150°C, cold scraps.

Grinding of all plastics, from TPU to PA 6.6, filled with glass up to 25%.

Optimal in-feed of the regrind material into dosing and feeding system.

Blowmoulding: Full range of granulators for small bottles, tanks and jerry cans to 200 lt, coex fuel tanks 15 kg, IBC container, without pre-cutting.

Start-up grinding up to 23.000 bottles/hr of 0,75 lt, without fly-back.

Extrusion: Manual feeding at 1,5 m sheets, pipes and profiles 6 m long.

Grinding chamber with 3, 5 or 7 rotating knives, for processing all resins, PLA, ABS, EPS, PET and all products, expanded, honeycomb, full and deep sheets.

Film: Inline recovery of edge trims CPP and LLDPE up to 1.000 m/min and 600 kg/h.

High density of flake, up to 150 g/dm³, gives ease of feed back to the production machine.

Complete system from edge trim intake to extruder throat or storage container.

Thermoforming: Granulators cater for 100 to 5.000 kg/hr at start-up of full sheets, sheets with cups and skeletal waste.

Sheets width from 600 mm to 2.000 mm, up to 250 mm products height up to 3 mm thickness.

Granulators installed under trim press or stacking station, at the end of the line or into a pit to be perfectly matched to all thermoforming machines.

Granulators and Shredders

Mediums speed online granulator – The medium-speed crusher is suitable to be placed around the injection moulding machine and used in conjunction with the recycler and dryer to form a fast recovery system.

Slow-speed online granulator – Slow speed crusher occupies less land, low energy consumption, and can be used continuously throughout the day; Multiple models are ready for selection, suitable for the recycling of nozzle materials of different sizes.

European granulator – This machine can not only crush waste products produced in injection moulding, but also crush pipes, profiles, sheets, materials, containers, TV casings, car bumpers, etc. Wait. It has the characteristics of economy, durability, easy cleaning, and long service life.

Soundproof granulator with collector – Four types of knife-shaped crushers can be made into silent models, suitable for processing different materials; The whole body adopts a fully enclosed structure and is provided with a sound insulation device, which can effectively reduce the noise generated during crushing.

Claw type granulator – Adopting the design of the front knife set, increasing the cutting angle of the blade, improving the cutting efficiency, the particle shape after crushing is uniform, and the powder is small; The claw-shaped knife set is better for large rubber head materials or materials with higher hardness.

Flat type granulator – Adopting the design of the front knife set, increasing the cutting angle of the blade, improving the cutting efficiency, the particle shape after crushing is uniform, and the powder is small; The flat knife set is suitable for various blow moulding parts, hollow products, various film products, such as PET bottles.

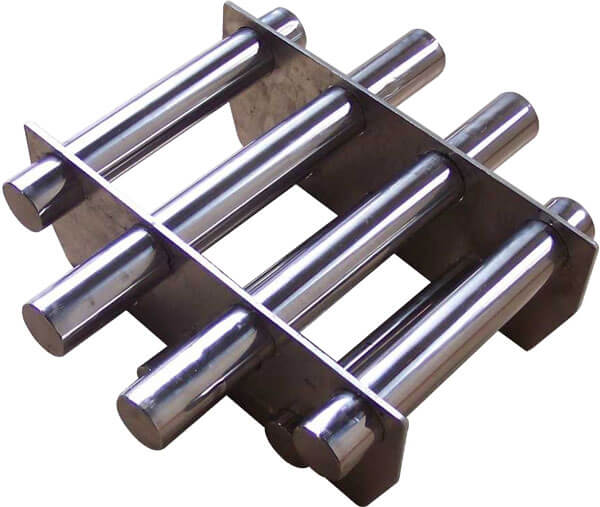

Magnets

Hopper Magnets are used to protect plastic processing machinery from metal contamination. Kaifeng offers various sizes to suit every application.

Melt pressure and temperature instrumentation

Dynisco is known worldwide for leading-edge pressure and temperature measurement and control products for the plastics extrusion industry. More than a parts supplier, Dynisco specializes in developing solutions to address the many processing challenges of extrusion, moulding, and process control applications. Dynisco products are designed and manufactured to the highest quality standards

Robotics and Automation

Abiman provides solutions required to establish and manage an optimum manufacturing environment to hardware, software, and smart factory.

They are constantly striving in the development of injection moulding, robotics, and processing automation industry in accumulating the necessary know-how.

Abiman’ s robots have been proven and satisfied customers for years with its optimal design, know-how, reliable battlefield configuration, and exceptional scalability to respond to a wide range of injection-type businesses.

- Adaptation Optimization, Robot Design

- Reproducibility & Business Scalability

- Optimal robot control solution for powerful, automated performance

- Work Environment Improvement and Safety Improvement Solutions

- Energy Efficiency Solutions

- User Experience Optimization Solution

Cooling water flow regulators

The function of a Flowise flow regulator is to control the mould cooling water for injection, extrusion, diecasting machines, or other applications where it is necessary to manage fluid control.

Flowise Flow regulators are made of 50- or 60-mm plexiglass© machined blocks, tested at 20 bar to guarantee no water leaks. They are equipped with double manifolds (water to mould and from mould) and with only regulation and visualization of flow. Flowise water flow control devices are different for hydraulic connections that can be under the frame (5 Serie) or back (2 Serie) equipped with adjustable water flow control brass valves. Flowise is the only water flow regulators manufacturer that produces a modular system: blocks from 1 to 6 zones can be assembled up to 24 zones with a central manifold and back hydraulic connections for the best flow distribution. The water flow rate regulation is visible on-screen printing scale using 4 interchangeable different floats made in PVC, red anodized aluminium and brass, each one has a flow range: 0-3,5 Lpm(PVC) 0-8,3 Lpm(red anodized aluminium) 1-15 Lpm(brass type 1) 4-25 Lpm(brass type 2).

Intelligent temperature control technologies