Mould & Die Components

Achieving precision in mould making and die casting is as much an art as it is a science, which is why Hestico has curated a selection of Mould & Die Components that stand up to the exacting standards of the industry. Our handpicked products are designed to enhance your operations, minimise downtime, and improve the overall quality of your output.

Our inventory extends from advanced purging solutions that effortlessly clean your plastifying elements, to pinpoint-accurate hot runner controllers that ensure consistent temperature regulation. Fine-tuning the details of each mould and die is hassle-free with our top-of-the-line polishing equipment and unmatched precision cutters.

Take a closer look below at how our offerings can seamlessly become a part of your workflow, maintaining the high standards of quality and efficiency that your business is known for.

Purging emulsion

Polishing equipment

Diprofil supply Machines : Ultrasonic Finishing Machines, Di-PRO Air-driven, Flexible shaft driven, Micromotor driven. Diamond and CBN : Machine Files, Hand Files, Grinding Pins and Points, Grinding Wheels, Cutting Discs. Lapping and honing : Wood Bobs, Felt Bobs, Lapping Rings, Lapping Ribs, Polishing Sticks, Lapping Bits, Polishing Stones, Super Stones. Precision Tungsten Carbide Cutters. Precision Steel Files. Diamond Compound.

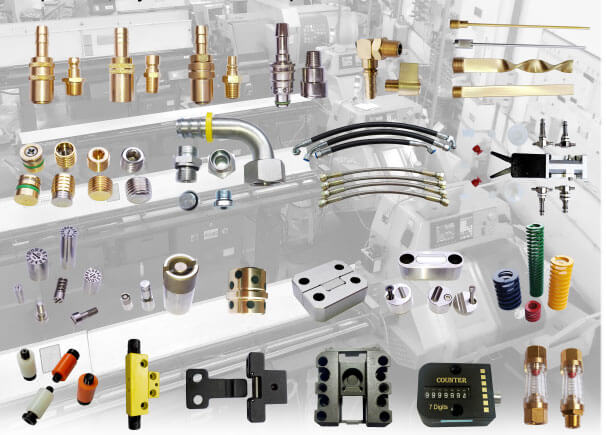

Mould components

Mould components for the plastic injection moulding industry.

For over six decades, D-M-E has been helping moldmakers, mold designers, and molders be more efficient, more productive, and more profitable. Our full line of mold bases, components, and hot runner solutions are all engineered for maximum performance. With the industry-leading catalog of mold technologies, no one offers you more than D-M-E.

Hot runner controllers

Mould components

SLD Enterprise Incorporation Ltd. was founded in February 2005 in Hong Kong and it’s a subsidiary of SLD China founded in April 1998. In the very beginning, it sold mould couplings, water connectors and nipples & divergences.

In April 2001, to meet the demand from the mould & plastic injection industry, it set up its own factory with advanced equipment & detecting apparatus imported from Japan & Taiwan.

Due to high quality & reasonable pricing, SLD has become a famous manufacturer & seller in the field of plastic injection & mould components in China in the past decade. In the aim of developing international markets, SLD set up its subsidiary in Hong Kong in 2005. Now SLD is selling components to over 43 countries across the globe.